| Product Name: | ZJE-1000L |

| Capacity(L): | 500L~1000L Customizable |

| Weight(KGS): | 1200kg |

| Heating Method: | Electric/Steam |

| Power(KW): | 6KW - 30KW |

| Voltage(V): | 220V-380V |

| Material: | SUS304/SUS316/red Copper |

| Application: | Whisky/Vodka/Brandy etc. |

| Certificate: | CE / UKCA / ISO9001 |

High production capacity for large-scale operations

Efficient steam heating for superior essential oil extraction

Durable, high-quality construction

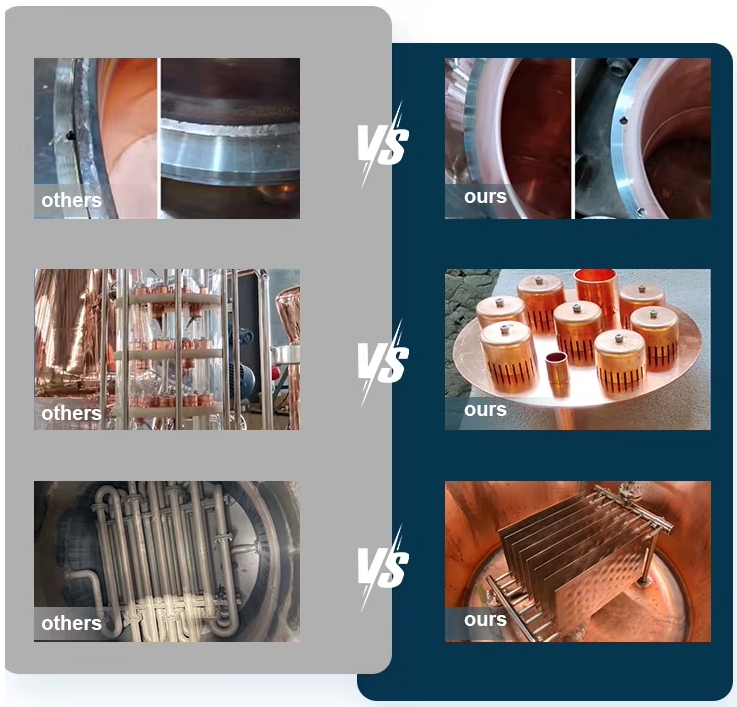

Enhanced Thermal Conductivity: TP2 red copper is renowned for its excellent heat transfer properties, allowing for rapid heating and cooling. This ensures precise temperature control during distillation, leading to consistent and high-quality spirit production.

Flavor Purification: Copper's unique ability to react with sulfur compounds present in the distillate helps eliminate unwanted flavors and odors. This interaction results in a smoother and more refined spirit, enhancing the overall taste profile.

Structural Integrity and Durability: 304 stainless steel provides exceptional resistance to corrosion and mechanical stress. Incorporating this material in the distiller's construction ensures a longer lifespan and reduces maintenance requirements, offering a cost-effective solution for distilleries.

Ease of Maintenance: The non-porous surface of stainless steel simplifies the cleaning process, minimizing the risk of contamination and ensuring consistent product quality.

The essential oil distillation process is a precise method that ensures the purity and potency of natural plant extracts. It typically follows these key steps:

Harvesting & Preparation – Fresh or dried botanicals are carefully collected and prepared for distillation to preserve their aromatic compounds.

Steam Generation – Water is heated to create steam, which passes through the plant material and gently releases volatile oils.

Condensation – The steam carrying essential oil vapors is cooled in a condenser, turning it back into liquid form.

Separation – The liquid mixture separates into two parts: essential oil and aromatic water (hydrosol).

Collection & Storage – Pure essential oils are collected, filtered, and stored in dark glass containers to maintain quality.

This step-by-step essential oil distillation process ensures high-quality oils with maximum therapeutic value, making it the preferred method for professional aromatherapy and natural product industries.