When we visit a distillery, we can see most of the external structure of the distillation equipment, but we may not know the names of the components. Today, we will use the pot still to explain the names of each part.

Pot: The main container used for storing the distillate and heating it. It comes in various shapes and sizes. The pot must be connected to pipes and valves for loading and unloading. If steam heating is used, it must also be connected to steam pipes and valves. Other auxiliary facilities include vent valves and cleaning manholes. The capacity of the pot is calculated based on the maximum safe volume of distillate it can hold. In practice, it is not filled to capacity; typically, it is filled to about two-thirds, keeping the liquid level below the manhole. In fact, the filling volume of each distillery is not determined solely by the pot capacity but must be considered in conjunction with other equipment, including the capacity and number of mash tuns and fermentation tanks.

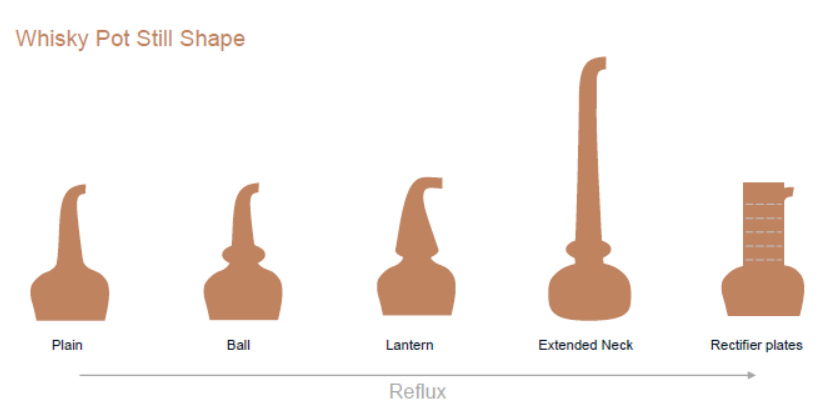

Wash Still: The main component of the commercial pot still is copper, which helps purify excessive sulfides and reduce undesirable off-flavors and notes such as rubber. Depending on the shape of the still, it can be classified as straight, bulb-shaped, lantern-shaped, long-necked, or column-shaped. For example, some stills have a noticeable narrowing at the junction between the pot and the neck, which is related to reflux. As alcohol vapor rises, the narrowing at the neck slows down the movement of the vapor, lowering the temperature of the copper surface and making it easier for the vapor to cool, condense, and reflux. Some distilleries even expand the structure after the narrowing, creating a bulb (referred to as a "bulge" or "ball"). This allows the rising vapor to cool down upon entering the bulb, increasing the reflux rate and producing a new make spirit with delicate and elegant flavors. Depending on whether the still has a narrowed neck or a bulb, it can be classified as onion-shaped, straight, long-necked, or bulb-shaped. Stills with a narrowed neck or a bulb can increase the reflux rate, resulting in a more refined and elegant spirit.

Swan Neck: The neck extending upward from the pot, combined with the pot, forms various shapes such as onion, pear, lantern, or bulb, with different heights and widths. This allows the vapor to rise, condense, and flow back down the copper walls into the pot, enhancing the interaction between the vapor and the copper. This process is considered decisive in shaping the style of the new make spirit. A small number of distilleries install a "water-cooled jacket" on the neck, which further increases reflux.

Lyne Arm: The copper arm extending horizontally from the swan neck to connect to the condenser. Its angle—upward, horizontal, or downward—also plays a decisive role in shaping the style of the new make spirit. A steep upward angle increases the reflux rate, allowing more interaction between the vapor/liquid alcohol and the copper. A steep downward angle reduces the reflux rate, allowing the vapor to pass through the arm quickly with less interaction with the copper. Some distilleries have Lyne arms that bend upward or downward, following the same principle. Many distilleries install various forms of "purifiers" on the Lyne arm to increase the reflux rate.

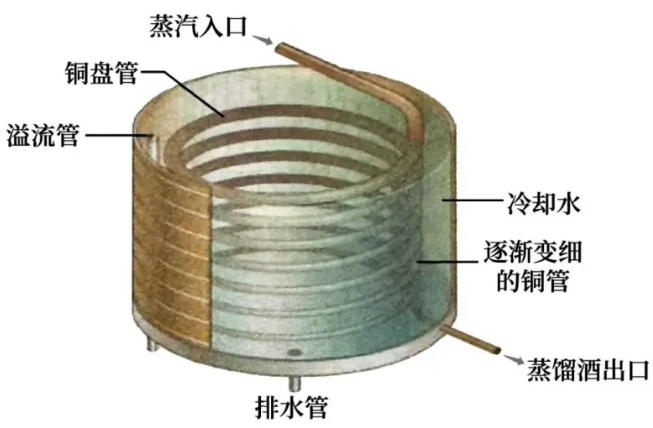

Condenser: The condenser is used to condense alcohol vapor. There are two types: worm tubs and shell-and-tube condensers. Traditional condensers are worm tubs, which were the most popular until the 1960s. They consist of a copper pipe with the same diameter as the end of the Lyne arm, gradually reducing in diameter until it shrinks to about 76mm at the safe box. This can be seen as an extension of the Lyne arm. It is a long, slender pipe coiled like a worm and immersed in an open cooling tank made of wood or iron.

For distilleries, it is large in size (some are over 100 meters long), expensive, consumes a lot of water, and makes energy recovery difficult. Today, only a few distilleries in Scotland still insist on using them, even though modern commercial distilling equipment for sale offers more efficient and sustainable alternatives. Shell-and-tube condensers use an upright copper cylinder with many fine copper tubes inside. During operation, cooling water flows upward inside the copper tubes, exchanging heat with the external alcohol vapor. The temperature of the cooling water gradually rises. The alcohol vapor condenses and flows down along the copper tube walls, gradually cooling. The temperature at the bottom of the condenser is about 20°C. After the heart cut is taken, it flows into the safe box.

Spirit Safe:Every whisky distillery has a locked brass box next to the stills, all looking similar in appearance. Behind the locked glass front cover of this brass box flows a transparent, colorless liquid—the newly distilled whisky spirit. Since its inception nearly 200 years ago, this brass box has played a crucial role in spirit distilling equipment, to the extent that its name carries a certain mystique: the Spirit Safe. Through the spirit safe, the new make spirit can be observed and measured, with indicators including alcohol strength and temperature. The technician uses their experience to determine when to cut the heart of the run.